What is the dew point? Every container contains moisture, even if it is not always visible. Even before the goods are loaded into the container, a measurement will show with 100% certainty that there is moisture (water vapor) in the air. Moisture is in the container floor that has been cleaned, in the pallets that have been outside for some time, and in the packing material in which the goods are packed. At first glance, therefore, there may be the perception that the container is dry, when in fact the amount of invisible moisture in the air may be significant.

Temperature fluctuations

Temperature variations during transport cause the water vapor in the air to condense, turning into liquid. Terms often mentioned in relation to this physical process are relative humidity and dew point.

Difference of relative humidity and dew point

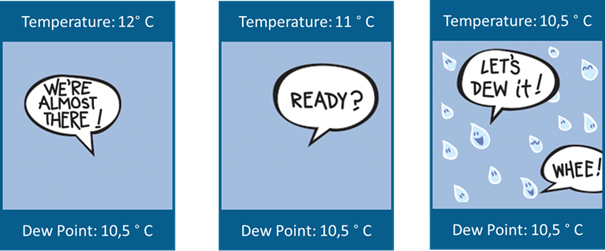

You are probably wondering what the big difference is between dew point and relative humidity. The amount of moisture in the air relative to the amount of moisture the air can contain is the relative humidity. This percentage can fluctuate due to supply of warm or cold air. As the temperature drops, the relative humidity will increase. When it reaches 100% relative humidity, the air is saturated and drops or condensation form. This can be in the form of fog, dew, frost or in a container as condensation and container rain.

The dew point is basically the temperature at which the air is saturated with water vapor so that condensation occurs. There is no fixed value for the dew point, as it depends on the amount of water vapor in the air and the degree of temperature variation. At a relative humidity of 100%, the dew point is equal to the air temperature.

Condensation

Condensation is a physical process in which water changes from vapor to liquid state: the water vapor turns into water droplets. In a shipping container, we then speak of condensation or container rain. This occurs when the dew point temperature is reached. Moisture in a container can have serious consequences for the goods it carries. Just think about wet boxes, loose labels, corrosion, mold and odor. Waste is the result, and that’s exactly what we want to prevent.

How we don’t give moisture a chance

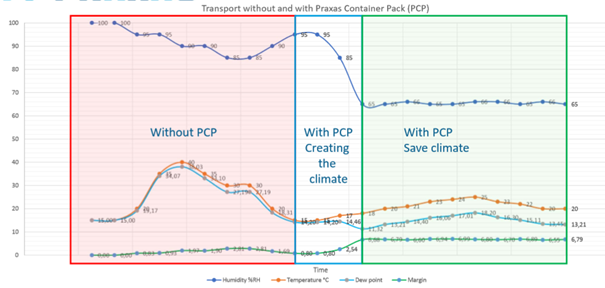

As mentioned, there is always moisture in a container, and this is also almost impossible to avoid. The challenge, therefore, is to keep the moisture contained in the air from reaching the saturation point where it is converted into water droplets: condensation. You create this by stabilizing temperature fluctuations. With the Praxas Container Liner Plus, the container is protected in such a way that the chance of reaching the dew point is zero. This can also be seen in the graph below.

Without protection, the temperature varies considerably and the dew point goes with it. Humidity is also high. The higher the humidity, the closer the dew point is to the temperature of the air. The chances of the temperature reaching the dew point are high. By now you know what happens then. By using the Praxas Container Liner Plus, a climate is created inside the container that ensures that the temperature remains stable despite outside temperature fluctuations. You can see that humidity drops sharply and remains stable, and the difference between air temperature and dew point increases.

Protecting your goods

It’s a physics game that can sometimes be complicated to explain, but it says a lot about the conditions goods can be in a container. As much as $500 billion in goods are lost annually due to container damage, ten percent of which is due to moisture. These are frightening figures, and our goal is to reduce them significantly in the coming years, with the Praxas Container Liner Plus as our main tool.

Watch the video of how the Praxas Container Liner Plus works here.

Look here for more information, or contact us. We can tell you all about the product, the application, the cost and what it will ultimately give you.