In healthcare facilities, the temperature of medication in refrigerators is often recorded manually. In practice, this means that an employee of the institution goes through all refrigerators every day to check and record the temperature of the medication. This data is then manually entered into the system. For healthcare facilities with multiple locations, this is a cumbersome, time-consuming and therefore expensive process. Praxas believes this can be done more efficiently. In this practical study, we show how healthcare facilities can greatly increase efficiency by digitally centralizing data.

Background of the practice case

Like many other institutions, the healthcare facility on which this case is based is responsible not only for the daily care of its residents, but also for administering medication. The organization is located centrally in the country and there are 11 locations. There is an attending physician attached to each location and the storage of medication is done per location. Sometimes medication is transported from one of the locations to another. Much attention is paid to monitoring and recording the temperature of medication to meet strict internal and external quality requirements.

Current practice by location

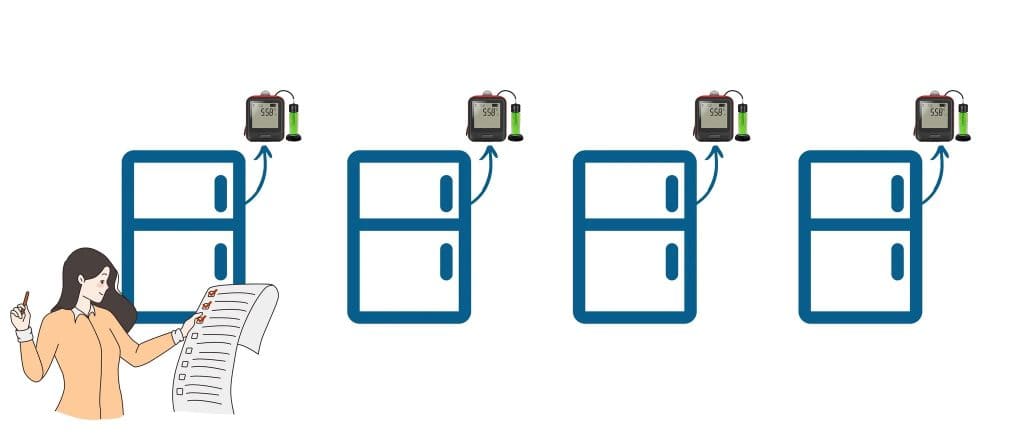

There are four refrigerators per location. All refrigerators are equipped with a temperature logger on the inside. The temperature in the refrigerator must always be between 2 and 8 degrees Celsius. A staff member checks the temperature in all refrigerators daily.

Monitoring and recording the temperature in the refrigerators

The employee compares the set temperature of the refrigerator with the data on the display of the temperature logger. If these values do not match, immediate action is taken. Once a month, the temperature logger is connected to a PC via USB and the data is exported to Excel. The employee records any temperature exceedances and describes the actions that were taken to ensure the quality of the medication.

It is mandatory to record and keep the temperature data. During an audit, the employee must be present to hand over the log and provide explanations if requested.

Monitoring during transport of medication

In addition to monitoring and recording the temperature in the refrigerators on site, the employee is also responsible for recording temperatures during transport. The thermobox used for transport also contains a temperature logger. Data from the logger is exported to Excel after transport. This data must also be submitted during an audit.

Disadvantages of the current approach

Recording the temperature data of all refrigerators in all locations daily and exporting that data regularly are time-consuming operations. Moreover, a manual procedure is very error-prone.

The hardware with built-in temperature sensor is very sensitive to ambient temperature. This causes error messages that are irrelevant to stock quality. For example, a sensor may respond to a heat flux when the refrigerator door is briefly opened. However, this does not mean that the temperature of the medication has risen to the same extent.

There is a huge shortage of healthcare staff, therefore every minute that cannot be spent on a client is one minute too many. The pandemic put extra pressure on healthcare workers since March 2020. Actions such as logging temperature data were overlooked in the hustle and bustle of the hectic days.

If the temperature is not adequately monitored, the efficacy of the medication may decrease during treatment. In addition, there is an increased risk of medical complications if the medication was stored for an extended period of time in an environment that did not meet temperature requirements.

The request for help from the care facility

The healthcare facility asked Praxas for advice in implementing a central system that automatically monitors temperature at the 11 locations and takes action when values outside the set temperature limits are detected.

This system must meet a number of prerequisites. It must be easy to install, user-friendly and accessible to multiple employees. Data must be stored in a well-organized database and manual operations must be kept to a minimum. The system must be able to be used at both fixed and mobile locations, and it must make use of existing infrastructure. Expensive and time-consuming changes to the network are out of the question. A conclusive record must be able to be presented during an audit and the financial investment must remain within limits.

This was a very comprehensive set of logical prerequisites. Praxas offered a solution that met all these conditions.

Central storage of temperature data

Based on current shortcomings, requirements and boundary conditions, temperature loggers with a wifi module, sensor and glycol buffer were proposed.

The built-in wifi antenna can be very easily connected to any existing wifi network.

The external sensor with glycol buffer measures the core temperature of the medication, reducing the risk of erroneous readings.

For transports, a combination of a thermobox with a temperature logger was recommended.

The temperature logger communicates with an online platform. Data are stored centrally in the cloud and no manual logging is required. Temperatures are displayed clearly, per temperature logger. Authorized individuals are notified via an app or by email of any temperature exceedances. They can add a note on the platform about the cause of the report, the steps taken to resolve the problem and the state of the medication.

Because temperatures are recorded for each temperature logger, different locations can be compared. In addition, one can see which refrigerators are not performing well and may need maintenance or replacement.

The online platform can be accessed by multiple people. It is also possible to invite an auditor so that he or she has direct access to all data and can thus audit efficiently.

The result

The implementation of this solution has significantly increased the efficiency of the healthcare facility. The number of manual operations performed by employees has been greatly reduced. The central storage of data has minimized the risk of errors. The result is a conclusive logbook that is always up-to-date. Only authorized persons have access. Employees spend much less time monitoring and recording temperature data. As a result, this investment resulted in savings. Moreover, we did not even take into account the extra attention and care the patient receives as a result.

Also watch the video here:

Interested in this solution?

Would you like more information about implementing a centralized medication temperature monitoring system in your healthcare facility, general practice or pharmacy? Feel free to get in touch. Together we will look at how this solution can increase the efficiency of your workflow.