In this article, we’ll explore PFAS and how new regulations are impacting the garment industry.

PFAS (Perfluoroalkyl chemicals) are a type of DWR (Durable Water Repellent) coating that makes clothing resistant to water and oil. You’ll find DWR coatings in outdoor gear, sportswear, workwear, and even medical clothing. PFAS have been used for years because they’re highly effective. However, they are also toxic, which has drawn the attention of the European Union.

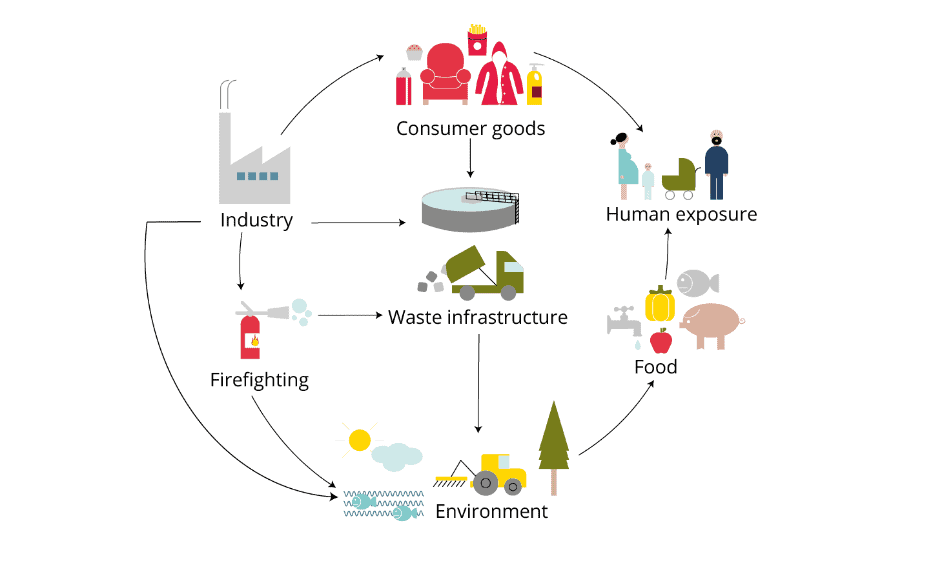

In 2009, the EU began restricting some types of PFAS. These chemicals, often referred to as “forever chemicals,” don’t break down naturally and can contaminate soil and water. Over time, they can build up in living organisms and have been linked to serious health problems. As a result, the EU is working to phase them out entirely.

The latest EU regulations are pushing garment and textile companies to change their DWR coatings once again. Previously, C8-based PFAS (named for their longer chemical chain) were banned, so the industry switched to C6-based PFAS, which have a shorter chain. However, the new restrictions now target these C6-based PFAS as well. This shift is creating new challenges for companies across the industry. Let’s dive into the consequences of this change.

Companies that have been using C6-based PFAS now need to find alternative substances to protect fabrics from water and oil. This change in coating can lead to new issues, such as mould developing on garments during transport.

Figure 1. Typical PFAS exposure pathways (Source: European Environment Agency)

In early 2020, a manufacturer reached out to Absortech after noticing mould on their clothing shipments from Asia to Europe. The problem? They had switched to a new coating to comply with the latest EU regulations, and it wasn’t providing the same protection as before.

“The first cargo shipment after changing the coating on the clothes, arrived in Europe in very bad condition. Clothes were full of mould. We never experienced those damages before and needed to understand why it happened to avoid it in following shipments.” – – Supply Chain Manager

The new client had been using silica gel pouches inside the polybags, but despite this, the garments still arrived in poor condition, leading to unexpected costs and delays. Absortech was ready to help and began by asking a few key questions:

- Are silica gel pouches not effective against the growth of mould?

- Do we need a bigger silica gel pouch inside the polybag?

- Will an AbsorGel® pouch avoid those moisture damages?

A false sense of protection

The company, a leading workwear manufacturer in Europe, relied on small silica gel pouches to protect their clothing. The garments were packed in polybags and placed in cardboard boxes for shipping and storage. At first glance, it seemed like the silica gel pouches provided enough moisture protection.

However, the real protection didn’t come from the silica gel.

PFAS (Perfluoroalkyl chemicals) are a type of DWR (Durable Water Repellent) coating that makes clothing resistant to water and oil. You’ll find DWR coatings in outdoor gear, sportswear, workwear, and even medical clothing. PFAS have been used for years because they’re highly effective. However, they are also toxic, which has drawn the attention of the European Union.

In 2009, the EU began restricting some types of PFAS. These chemicals, often referred to as “forever chemicals,” don’t break down naturally and can contaminate soil and water. Over time, they can build up in living organisms and have been linked to serious health problems. As a result, the EU is working to phase them out entirely.

The DWR coating on their clothes, which contained PFAS, was what actually protected them from mould during transport. When the coating was changed to comply with the new EU regulations, this indirect protection disappeared. As a result, the silica gel pouches alone weren’t enough to prevent moisture damage, leading to a false sense of security.

Peace of Moisture Mind® in Action

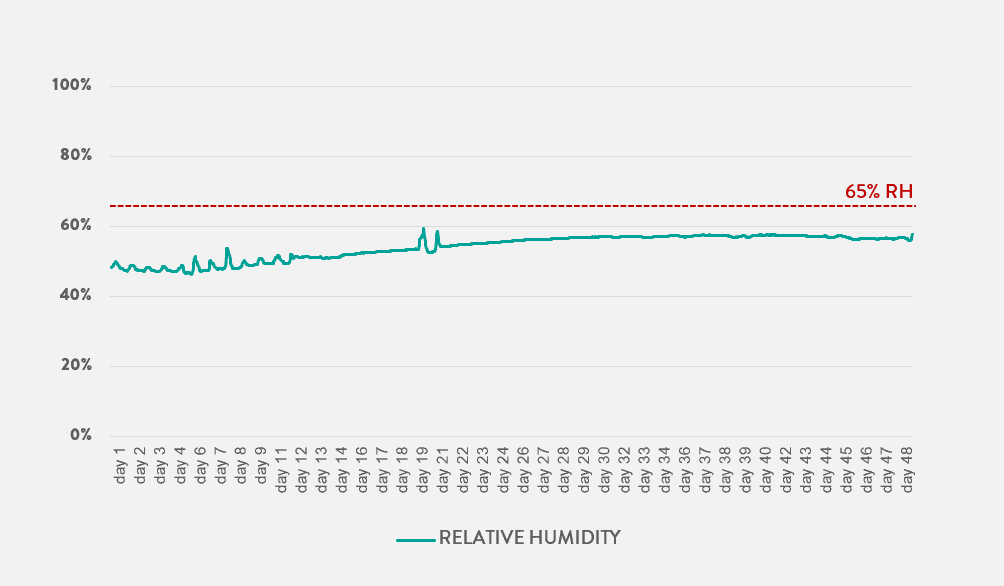

The situation demanded a swift response to prevent damage in future shipments. Absortech’s team in Asia promptly visited the production plants to audit the product conditions before shipping. They also recommended improvements to enhance the overall process. After the audit and implementing corrective actions, Absortech tested the effectiveness of the AbsorGel® Pouch D under real shipping conditions.

AbsorGel® Pouch D, which contains 94% pure calcium chloride and starch, is designed to absorb excess moisture in crates, cartons, polybags, and other types of packaging.

The tests revealed that the garments had been inadequately protected before. The AbsorGel® pouches absorbed significantly more moisture than the silica gel pouches, suggesting that the previous PFAS-based DWR coating provided most of the protection.

The AbsorTest™ results showed that AbsorGel® pouches maintained safe humidity levels inside the polybags, preventing mould growth upon arrival.

Additionally, the desiccants had plenty of capacity left, offering extra protection against unexpected issues like extended storage or changes in transport conditions.

The Broader Impact of the PFAS Ban

As the European Union progresses towards banning all non-essential uses of PFAS, various industries will face new challenges. It’s not just the garment and textile sector that will be affected; other industries may also encounter similar issues as they adjust to the new regulations.

AbsorGel® has proven to be highly effective in protecting garments and fabrics from moisture damage during transportation. It is also an excellent choice for companies aiming to safeguard their brand while supporting environmental sustainability.

For PDF click here